NanoXplore and STMicroelectronics deliver European FPGA for space missions

- NanoXplore’s NG-ULTRA FPGA becomes the first product qualified to new European ESCC 9030 standard for space applications

- The product leverages a supply chain fully based in the European Union, from design to manufacturing and test, and delivered by ST

- Its advanced digital capability enables European customers to develop higher performance, more competitive satellites and space missions

Media Relations

NanoXplore

Lucie Paturel

+33 6 11 69 09 59

lucie.paturel@nocom.com

STMicroelectronics

Alexis Breton

+33 6 59 16 79 08

alexis.breton@st.com

Stay tuned

To receive frequent updates via email, subscribe to our press releases.

NanoXplore, the European leader in the design of SoC FPGA and radiation-hardened FPGA technologies, and STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, announce the qualification of NG-ULTRA for space applications. This radiation-hardened SoC FPGA has been designed specifically for space applications, including low- and medium-earth orbit constellations, and is set to be used in numerous satellite equipment systems, including flagship missions such as Galileo, Copernicus, and potentially IRIS².

“The ESCC 9030 qualification for the NG-ULTRA is a historic step. It proves that Europe now masters the entire production chain for cutting-edge digital components tailored to the requirements of both deep-space and new space constellations. Thanks to the support of the ESA, CNES, and the European Commission (via DG-DEFIS), NanoXplore & STMicroelectronics are securing EU strategic autonomy while making European satellites more competitive than ever.” — Édouard Lepape, CEO, NanoXplore.

“Space applications require robust sovereign supply chain, radiation-hardened and cost-optimized chips. ST is leveraging its expertise in GEO and LEO platforms with proven FD-SOI technology, hardening expertise, manufacturing, advanced packaging and quality assurance assets in Europe to enable NanoXplore’s NG-ULTRA to the New Space market,” said Thomas Goust, Division General Manager of Space Division, RF & Optical Communication sub-group at STMicroelectronics.

First product certified to ESCC 9030 for the European New Space industry

This qualification marks a major industrial and technological milestone for the European space ecosystem: NG-ULTRA is the first product qualified to ESCC 9030, a new European standard dedicated to high-performance micro-circuits in flip-chip’ed on organic substrate or plastic package. This standard delivers the reliability required for space applications while enabling a transition away from traditional ceramic-packaged solutions – well suited for deep-space but heavier and more expensive – marking a key step forward for constellations and higher-volume missions.

The “new space” dynamic (constellations, Low and Medium Earth Orbits, higher volumes) is transforming requirements for onboard digital equipment and driving a shift in scale: there is a simultaneous need for greater computing power, controlled power consumption, and contained costs compatible with large-scale deployments. NG-ULTRA addresses this challenge by enabling more data to be processed directly in orbit (edge computing), thereby limiting transmission bottlenecks between space and ground.

NG-ULTRA targets strategic functions such as on-board computers, data management and routing between sub-systems, image and video processing (real-time compression and encoding), Software Defined Radio (SDR) – enabling remote evolution of communication modes, and onboard autonomy (detection, recognition, supervision).

A secure, European supply chain

Beyond performance, this program embodies a strategic ambition to secure a sovereign and sustainable European supply chain for long-duration missions by reducing critical dependencies. For NG-ULTRA, the industrial framework combines design, manufacturing, assembly, and testing capabilities across European sites, with the aim of reconciling competitiveness, volume production, and space-grade reliability.

In addition to its own R&D and design center in Paris, Grenoble and Montpellier, NanoXplore leverages various STMicroelectronics facilities in Europe, including the Grenoble R&D and design center, the 300mm digital fab of Crolles, the space-specialist packaging facility in Rennes (France), the test and reliability site in Grenoble (France) and Agrate (Italy) and additional redundant qualified sites in Europe.

Technical specifications

With an “all-in-one” SoC (System on Chip) architecture designed specifically for platform and onboard computing applications, NG-ULTRA combines a multi-core processor with programmable hardware on a single chip. This architecture allows for greater design agility, reduces electronic board complexity and component count, and optimizes latency, mass, and power consumption.

NG-ULTRA is built on STMicroelectronics’ 28nm FD-SOI digital technology platform, recognized for its advantages in energy efficiency, resistance to space radiation and advanced architecture features. Combined with a unique advanced radiation hardening technology, the NG-ULTRA is built to survive the thermal cycles, shocks, and vibrations of launch and long-term orbital life so as to ensure best in class performances and durability in the harsh space environment throughout the mission lifetime.

The NG-ULTRA has been designed to operate reliably in harsh radiation environments, offering a Total Ionizing Dose (TID) tolerance of up to 50 krad (Si) to ensure long-term performance. It also demonstrates strong resilience to single-event effects, with Single Event Latch-up (SEL) immunity tested up to 65 MeV·cm²/mg and Single Event Upset (SEU) immunity validated for Linear Energy Transfer (LET) levels exceeding 60 MeV·cm²/mg.

NG-ULTRA integrates a full SoC based on quad core Arm® Cortex® R52 and provides high computational capability (537k LUTs + 32 Mb RAM) to address the most complex onboard computer requirements.

Its streamlined architecture drastically reduces PCB complexity and system mass—two of the most critical constraints in space design. By minimizing the component count, the NG-ULTRA simultaneously lowers total power consumption and project costs while increasing overall system reliability.

In addition, the SRAM-based architecture of the NG-ULTRA enables an adaptive hardware approach, allowing for unlimited on-orbit reconfiguration. This “hardware-as-software” flexibility allows operators to update functionality post-launch, adapt to evolving communication standards, or optimize the chip for different mission phases. The NG-ULTRA thus provides a future-proof platform that extends the operational relevance of assets long after they leave the launchpad.

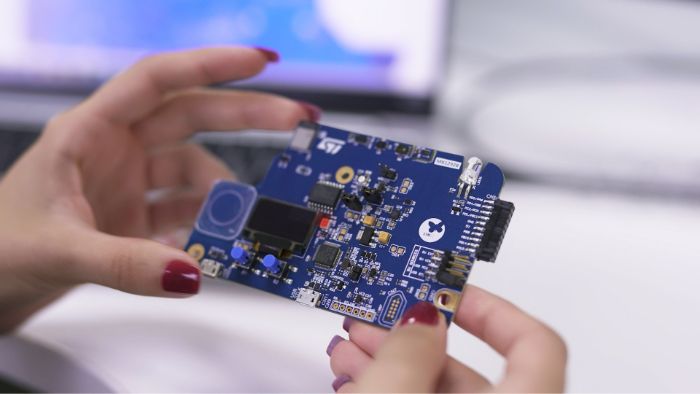

To facilitate adoption, NG-ULTRA is also available as an evaluation kit — a complete prototyping platform that allows to rapidly validate performance and interfaces, reduce integration risks, and accelerate software and onboard logic development prior to flight-board production.

About NanoXplore

NanoXplore is a French fabless company designing radiation-hardened FPGA components for high-reliability environments, specifically space and avionics. The company recently launched the NG-ULTRA, the world’s most advanced radiation-hardened FPGA SoC. With an international presence, NanoXplore is the European leader in the design and development of SoC FPGA technologies and a key partner to the major players in the aerospace sector.

About STMicroelectronics

At ST, we are 50,000 creators and makers of semiconductor technologies mastering the semiconductor supply chain with state-of-the-art manufacturing facilities. An integrated device manufacturer, we work with more than 200,000 customers and thousands of partners to design and build products, solutions, and ecosystems that address their challenges and opportunities, and the need to support a more sustainable world. Our technologies enable smarter mobility, more efficient power and energy management, and the wide-scale deployment of cloud-connected autonomous things. We are on track to be carbon neutral in all direct and indirect emissions (scopes 1 and 2), product transportation, business travel, and employee commuting emissions (our scope 3 focus), and to achieve our 100% renewable electricity sourcing goal by the end of 2027. Further information can be found at www.st.com.

Downloads

Media Relations

NanoXplore

Lucie Paturel

+33 6 11 69 09 59

lucie.paturel@nocom.com

STMicroelectronics

Alexis Breton

+33 6 59 16 79 08

alexis.breton@st.com

Stay tuned

To receive frequent updates via email, subscribe to our press releases.