An interview with Marco Cassis, President, Analog, Power & Discrete, MEMS and Sensors Group, Head of STMicroelectronics’ Strategy, System Research and Applications, Innovation Office.

Marco Cassis, President APMS, explains the importance of sensing technologies for artificial intelligence (AI) and how STMicroelectronics’ acquisition of NXP’s microelectromechanical systems (MEMS) sensors business will help broaden ST’s sensor portfolio to embed more intelligence in new applications and use cases.

Marco Cassis, President APMS, explains the importance of sensing technologies for artificial intelligence (AI) and how STMicroelectronics’ acquisition of NXP’s microelectromechanical systems (MEMS) sensors business will help broaden ST’s sensor portfolio to embed more intelligence in new applications and use cases.

Why are intelligent sensors crucial for AI development and emerging physical AI systems?

AI relies on data, and intelligent sensors are the entry points that capture and process this data. For scalable and sustainable AI, sensors must do more than collect information: they need to embed intelligence to enable faster responses, energy efficiency, and privacy protection. This “sense and process” paradigm is a significant opportunity for companies like ST, which lead in both sensing and processing technologies.

Data is the oil that powers the digital economy, and sensors are the engines that extract it from the physical world. ST’s vision is to enable smarter, more efficient devices by integrating AI capabilities directly into sensors. This approach allows sensors not only gather precise data but also analyze it locally, enabling applications across automotive, industrial, consumer electronics, and robotics. The goal is to make sensing more intelligent, efficient and privacy-preserving through edge processing.

How does ST position itself as a leader in sensing?

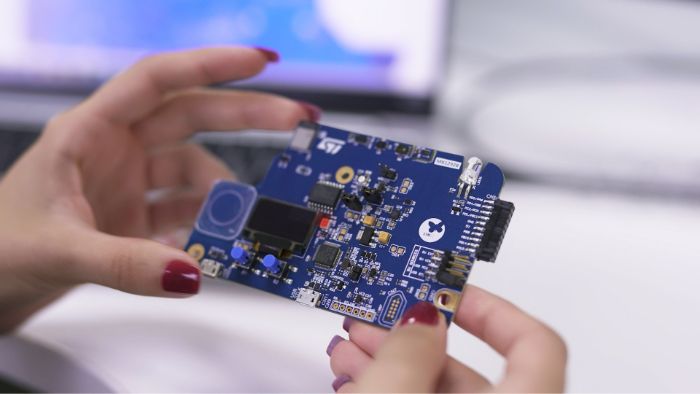

ST is unique in mastering both MEMS and imaging sensors. The company pioneered these fields over 30 years ago and has shipped more than 30 billion sensors worldwide. MEMS sensors, initially focused on consumer electronics, are now rapidly expanding into automotive and industrial markets due to their compact size, cost-effectiveness, and performance, with increasing intelligence embedded in products. In imaging, STMicroelectronics leads in Time-of-Flight and specialized CMOS sensors. Beyond hardware, the company provides a comprehensive development ecosystem compatible with the STM32 platform and ST Edge AI Suite, supporting customers from design to deployment.

What are MEMS sensors and why do they matter?

MEMS sensors are tiny devices combining mechanical and electronic components to detect physical phenomena like motion, pressure, or temperature. They serve as the bridge between the physical and digital worlds, enabling devices to perceive and interact with their environment. This is critical for applications ranging from smartphones and wearables to industrial machine monitoring, vehicles, and robotics. MEMS sensors uniquely integrate mechanical movement on chip, to provide accurate measurements for parameters such as acceleration, pressure, temperature, vibration, and angular rate. This capability is essential for a wide range of applications, including stabilizing a smartphone camera, detecting complex gestures in a wearable device, monitoring machine health in industrial settings, and enabling a humanoid robot to work in a factory. MEMS sensors are key to creating AI-driven, smarter, safer, and more responsive systems.

Why did ST acquire NXP’s MEMS sensor business?

ST and NXP’s MEMS portfolios complement each other, creating a balanced offering across automotive, industrial, and consumer sectors. This strengthens ST’s R&D, IP, and product roadmap, especially for automotive safety applications with inertial and pressure sensors, which are growing rapidly. It also broadens the company’s footprint in the industrial market, adding pressure sensors and accelerometers. The strong complementarity of technologies, products, and end markets will enable ST to better serve customers.

The enhanced R&D scale and complementary technologies create significant growth opportunities by meeting customer needs for new applications with innovative MEMS solutions. As industries move toward smarter, more connected systems, MEMS sensors enable better predictive maintenance, process optimization, and environmental monitoring.

How does this acquisition specifically strengthen ST’s automotive position?

The automotive industry is rapidly shifting as traditional cars evolve into software-defined vehicles (SDVs) powered by hundreds or thousands of sensors acting as the vehicle’s nervous system. These sensors collect and process ultra-low latency, high-fidelity data to enable safer, more efficient, and autonomous mobility. MEMS sensors serve as the vehicle’s sensory organs—detecting acceleration, pressure, vibration, and angular rate—while imaging and environmental sensors enhance perception for real-time, software defined control.

The acquisition of NXP’s MEMS sensor business strengthens ST automotive position by expanding its portfolio of inertial, pressure, imaging, and environmental sensors. These devices feed edge AI and central processors to support faster decision making and actions such as braking, steering, and power management.

What benefits does ST’s integrated model bring to the development of MEMS?

ST’s integrated device manufacturer (IDM) approach, covering R&D, design, manufacturing, marketing and sales under one roof, is key to delivering differentiated, high-volume MEMS products. This IDM model integrates the entire semiconductor value chain, from research and development to design, manufacturing, marketing and sales, enabling ST to maintain full control over the process. This model allows for rapid innovation, as seen in ST’s history of groundbreaking MEMS designs, such as the development of a robust single-pillar structure.

The company’s device manufacturing uses a mix of 300 and 200mm high-volume MEMS-specific and digital fabs: in Agrate, near Milan, Italy, and Crolles, near Grenoble, and Rousset, near Aix-en-Provence, France. While 300mm is the state of the art for the digital part of the sensors, the complexity of MEMS manufacturing means that 200mm is still state-of-the-art today.

STMicroelectronics’ activities in the Milano area, which include advanced research, development, and manufacturing of MEMS technologies and support the company’s leadership in sensor innovation and integration, form a worldwide hub for MEMS. We expect that volumes in ST’s MEMS fab in Agrate will grow in the coming years, durably supporting the loading.

Additionally, ST collaborates on MEMS R&D with top academic and research institutions globally including a new agreement with Politecnico di Milano, on research center for advanced sensor and the world’s first “Lab-in-Fab” to advance adoption of Piezoelectric MEMS in Singapore in partnership with A*STAR and ULVAC.

How does ST plan to lead this evolving landscape of intelligent sensing and AI integration?

We believe that ST’s expertise in both MEMS and imaging sensors, combined with its IDM model, positions the company uniquely to be a leader in innovative sensing technologies. The strategic acquisition of NXP’s MEMS business further strengthens this position. Our integrated approach ensures rapid development, high-volume manufacturing, and a broad, complementary product portfolio that addresses the evolving needs of smarter, connected systems.

Intelligent sensing contributes to advancements in AI either by embedding intelligence directly within the sensor or by enabling intelligent behavior in systems through data input. Each form plays a unique role in enhancing AI capabilities. The market opportunity is huge as devices from consumer electronics, to cars, and industrial environments become increasingly intelligent. Intelligent sensors are not just data collectors but active enablers of the AI revolution, and ST is at the forefront of this exciting journey.

Language Versions